Control Lines are widely used in many applications in the field of downhole and subsea. Younglee manufactures high quality control lines / control line tubing in stainless steels and nickel alloys.

Control Lines Brief Introduction

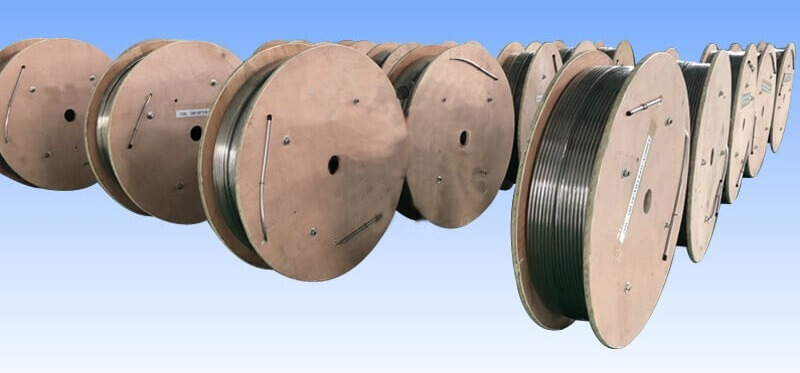

Control lines usually are coiled tubes made of stainless steel, duplex stainless steel or nickle alloys. The coiled tubes mostly are welded & redrawn tubes or seamless cold drawn tubes. Control lines are usually supplied with very long continuous lengths coiled on the drums.

Control lines are broadly applied in many applications, such as below:

- Downhole hydraulic control lines

- Downhole chemical control lines

- Subsea control lines for hydraulic power and chemical injection line

- Flowline control

- Instrumentation tubing

- Smooth inner surface control line tubing used in fibre optic applications

- Others

Control Lines Size Range

As one of the leading China control line manufacturer, Younglee produces full range of the popular control line sizes. Our control line tubing can be supplied in metric size and imperial size.

- Outer Diameter (OD): 3 mm (0.118”) to 25.4 mm (1.00”)

- Wall Thickness (WT): 0.5mm (0.020”) to 3mm (0.118”)

- OD tolerance +/- 0.005” (0.13mm) , other tolerances are available on request

- WT tolerance +/- 10%, other tolerances are available on request

- Tubing Coil lengths up to 6,000m (20,000ft) without orbital joints depending on product dimensions and its form (seamless tube or welded tube).

- Coil lengths up to 13,500m (45,000ft) with orbital joints

The most popular size of control lines are: 1/4″ control line, 3/8″ control line, 1/2″ control lines, 5/8″ control line tubes, 3/4″ control line tubing.

Control line materials

As the professional manufacturer of control lines, we produce control line tubing in material stainless steel 316L, duplex stainless steel 2205, 2507, Nickel alloy 825 & alloy 625.

Besides the above, we also make control line tubes with other materials upon customers’ request.

Control line tubing materials Chemical Composition

| Grade | UNS | C(max.) | Cr | Ni | Mo | Others |

| TP316L | S31600/S31603 | 0.03 | 17.5 | 13 | 2.1 | 0.1 |

| Alloy 825 | N08825 | 0.03 | 20 | 38.5 | 2.6 | Cu=1.7, Ti=0.7 |

| Alloy 625 | N6625 | 0.1 | 21.5 | >=58 | 9 | Nb=3.5 |

Control line tube materials Mechanical Properties

| Grade | Yield strength, | Tensile strength, | Elongation |

| psi (MPa) | psi (MPa) | % | |

| TP316L | 32,000 (220) | 75,000 (515) | 35 |

| Alloy 825 | 35,000 (240) | 80,000 (550) | 30 |

| Alloy 625 | 60,000 (415) | 110,000 (760) | 30 |

Control line material Corrosion Resistant Properties

| Grade | UNS | PRE | CPT F (oC) | Max H2S psi | CO2 |

| TP316L | S31600/S31603 | 24 | 95 (35) | No limit | + |

| Alloy 825 | N08825 | 29 | 140 (60) | No limit | ++ |

| Alloy 625 | N06625 | 52 | 195 (90) | No limit | ++ |

Control Line Tube Manufacturing Forms

As the professional manufacturer of control lines, Younglee makes long coils of control line tubing in three main forms as below:

- Seamless Tube – a billet of round bar is extruded or hot piercing into a tube and then cold rolled and drawn to final size.

- Welded and re-drawn Tube – a strip of metal is formed and being welded to a tube, then the tube is drawn through a mold to remove (homogenize) the weld seam. Some customers also call this type “seamless”.

- Welded and floating plug drawn – the weld tube is drawn through a mold with a floating plug in the bore to rework the weld seam internally and externally.

For more details on quality considerations, the advantages of redrawing welded tubes, and pressure calculations, please contact us for the control line datasheet.

Control Line Packing standards

- Control line tubes can be supplied as encapsulated, PVC coated or bare line tubing

- Control line tubes are supplied in Coil wound on wooden drum or spool.

- Coils wound on customer-specific metal reels

As one of the leading China control line tube factory, Younglee’s control line is widely supplied to customer domestic and abroad. Our control line tubes are exported to many customers in the oil and gas field in many countries, such as Russia, UAE, Saudi Arabia, Venezuela, Canada, USA, Brazil, Mexico, and so on.

We welcome customers all over the world to contact us for further information of our products of control line. Customers can contact us through:

Email: info@ylpipes.com

TEL: +86-17775807583